Save your work.

If for this type you want component yield effect in rollup then check this box.

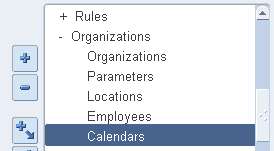

Once Cost Type is defined let’s Move forward to Defining and configuring Inventory Organization

SELECT SUM (target_qty)

, item_id

FROM (SELECT moqv.subinventory_code subinv

, moqv.inventory_item_id item_id

, SUM (transaction_quantity) target_qty

FROM mtl_onhand_qty_cost_v moqv

WHERE moqv.organization_id = :org_id

AND moqv.inventory_item_id = :item_id

GROUP BY moqv.subinventory_code

, moqv.inventory_item_id

, moqv.item_cost

UNION

SELECT mmt.subinventory_code subinv

, mmt.inventory_item_id item_id

, -SUM (primary_quantity) target_qty

FROM mtl_material_transactions mmt

, mtl_txn_source_types mtst

WHERE mmt.organization_id = :org_id

AND transaction_date >= TO_DATE (:hist_date) + 1

AND mmt.transaction_source_type_id =

mtst.transaction_source_type_id

AND mmt.inventory_item_id = :item_id

GROUP BY mmt.subinventory_code

, mmt.inventory_item_id) oq

GROUP BY oq.item_id

Latest Posts

- R12 – How to Handle NULL for :$FLEX$.VALUE_SET_NAME In Oracle ERPAugust 25, 2023 - 1:20 pm

- R12 – How to Delete Oracle AR TransactionsMarch 22, 2019 - 8:37 pm

- How to Define Custom Key Flexfield (KFF) in R12January 19, 2018 - 5:43 pm

- AutoLock Box Concepts In R12November 10, 2017 - 8:30 am

- R12 – java.sql.SQLException: Invalid column type in OAFSeptember 15, 2017 - 9:39 am

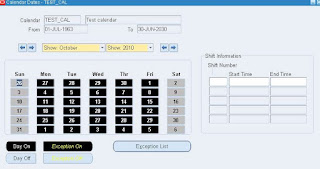

| S | M | T | W | T | F | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Recent Comments